People today use various storage products in their homes and in certain aspects of their lives. In addition to individual use, industrial usage of water tanks is quite common in the corporate sector. The materials used in the manufacturing of storage products have been determined through specific production improvement efforts. Two key factors were considered for the chosen raw materials: they should not interact with any content to be stored in any way, and they should be suitable for food contact. Based on the data obtained from these studies, the selected raw materials are polyethylene, polyester, and stainless steel. These selected raw materials do not interact with the content being stored, thanks to their rigid structures, which provide maximum protection for the stored content. We have conducted research to explain these materials and the components found in tanks, and what their functions are:

1) Polyethylene

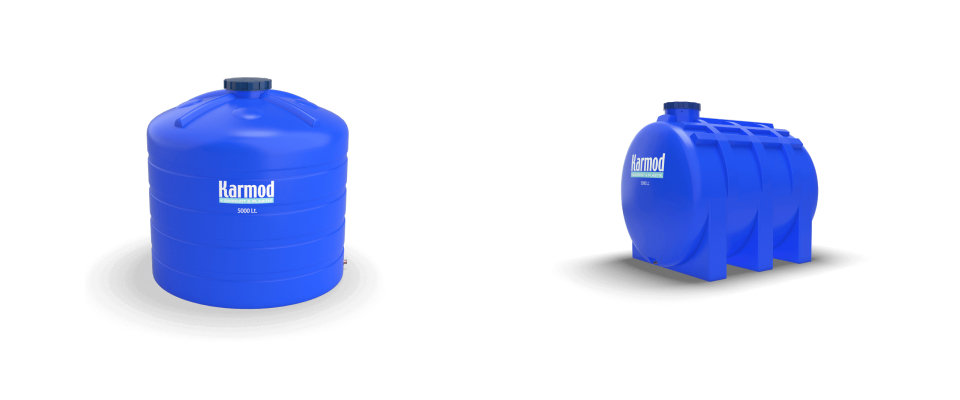

Polyethylene is commonly known as plastic among the public. In public opinion, polyethylene is considered a harmful raw material, but it has been accepted as food-safe by international food organizations. Furthermore, this raw material is easy to process, allowing for mass production. The Monoblock production system is used for this purpose. In the Monoblock production system, storage products are produced as a single piece. As a result, there are no rivets or seams on the tanks. Looking at the word's meaning, "mono" means "single" or "one," while "block" means "section" or "part." In addition to being produced in a serial manner, the design diversity is limited compared to other storage products. The size range is between 50 liters and 25 tons. The working temperature range for polyethylene is +50 degrees Celsius.

2) Polyester

Polyester stands out for its chemical resistance. Due to this feature, it is widely used for industrial purposes in industries that require chemical resistance. In simple terms, it is produced using fiberglass and polyester resin. However, polyester is the primary material obtained. The primary material obtained is combined using special adhesives in tank design, enabling on-site assembly for tanks made from polyester. These tanks can be produced in various designs and come in sizes ranging from 200 liters to 100 tons. It excels in chemical storage. The working temperature range for polyester is +60 degrees Celsius.

3) Stainless Steel

All storage products produced from stainless steel are considered highly durable. This is because steel's rigid structure makes it more resistant to impacts. Additionally, stainless steel storage products can be assembled on-site, much like polyester storage products. The primary material, stainless steel, is obtained by mixing chrome and nickel, and tank design is achieved by combining this material using argon welding. The size range is between 500 liters and 100 tons. As the size increases, a ladder is added to the stainless steel water tank design to facilitate access to the tank's cover. All storage products made from stainless steel are designed to be elevated above the ground, providing a more sterile storage solution. They have the highest working temperature range among storage products, which is +80 degrees Celsius. This value is very close to the boiling point of water, so it is recommended not to touch the tank after storing such hot content.

4) Sleeve

Sleeves are generally made of brass and are designed to prevent any leakage by using watertight gaskets. Additionally, they are food-safe sleeves, ensuring compliance with all food storage requirements. A faucet can be attached to the sleeve, making it a versatile component.

5) Lid

The lid of storage products is manufactured using the same raw material as the tank itself. This ensures compatibility between the lid and the tank. All lids are equipped with a screw system for easy opening and closing.

Common Features in Water Tanks

Water tanks have their advantages in terms of design, usage types, and materials. Besides these advantages, they share common features, making them all easy to clean and customizable in various color palettes. Thus, different contents can be easily categorized. We have conducted research to identify the common features of storage products. Here are the common features of storage products:

- UV Insulation

- On-Site Assembly

- Offering Size Variety

- Easy to Clean

- Design Variety

- Quality Raw Materials

- Production in Any Desired Color

- Two-Year Company Warranty

- Affordable Prices

As you can see, storage products offer a wide range of added value for both individual and corporate use. You can explore various models of storage products on our website. If you wish to purchase these storage products or obtain detailed information, please feel free to contact our customer representatives.

EN

EN

DE

DE

FR

FR

IT

IT

ES

ES

PT

PT

RU

RU

AR

AR

BG

BG

SR

SR

GR

GR

SQ

SQ

RO

RO

PL

PL

HU

HU

CZ

CZ

HR

HR

AZ

AZ

GE

GE

AM

AM

IL

IL