The material used in the production of water tanks is named according to the diversification of factors such as the method of production, area of use and purpose. When water tanks are mentioned, specially produced tanks that are used to store acid, diesel oil, paint and especially water come to mind

The tanks that have the most suitable price tag among water tank prices are the plastic water tank options. The most important factor that affects these water tank prices is the method of production. Because these tanks are produced as a monoblock, as in a single piece, they are quite durable and long-lasting. Fiberglass Storage Tanks Also, when looked at this point of view, these water tank prices that are produced using polyethylene remain quite affordable.

Since these tanks are used with purpose of storing water at best, they are generally referred to as ‘’water tanks’’. When we look at their general purpose of usage, they are tools that allows storing a liquid, a nutriment, chemicals or mixtures, depending on the situation, and use whenever needed by draining down. In accordance with the material used in the production, they are divided into production categories as polyester water tanks, polyethylene water tanks and stainless water tanks. Storage tanks produced from different materials can be used to store functionally the same liquids, also, each of them has a specific area of use. For example, all sizes of polyethylene or stainless tanks can be used for the conservation of water. However, stainless tanks should be preferred in areas that are exposed to heat such as heat-treatment furnaces.

Water Tank Models

Water tank models are also named after their method of production. Such as horizontal rectangle, vertical cylindrical, and horizontal cylindrical. Rectangle and cylindrical storage tank types are produced in all polyester, polyethylene and stainless products. The preference of vertical or horizontal water tanks are determined in accordance with the place and purpose of use. Vertical tanks provide fluidity under increased pressure when it is aimed to use the liquid inside with natural pressure.

When it is aimed to use the liquid with natural pressure inside the horizontal tanks, the natural flow of the liquid is ensured by placing them on a building or on a special carrier platform. Vertical cylindrical type tanks are especially preferred in homes where no central network is present or the outage is too frequent. In this type of tank, ergonomic usage is achieved without taking up too much space. Ranging from 100 liters to 25.000 liters, there are more than 30 different storage tanks produced with the polyethylene water tanks that are manufactured with Karmod expertise. Standard production is realized in exactly 95 different shapes and sizes, ranging from 200 liters to 100 tons with polyester water tanks. Polyester storage tanks consist of rectangular, horizontal and vertical cylindrical, and horizontal elliptical models. Vertical polyester storage tanks are also produced in metal support models for natural pressure.

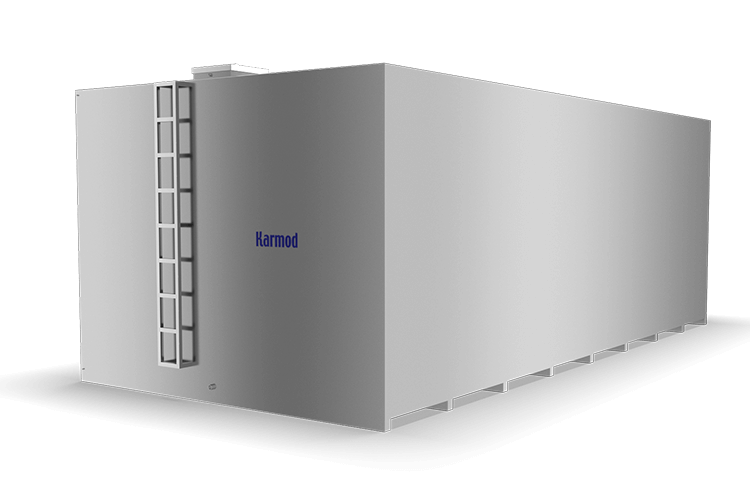

Karmod stainless water tank types are produced between 500 and 100.000 liters. Stainless storage tanks are produced in 50 different sizes including vertical and horizontal cylindrical and prismatic shapes. Stainless storage tanks are used in the storage of water, together with liquid chemicals in industrial facilities. Prismatic water tanks are in full compliance with the booster system and are used extensively in factories, especially in collective housing and social facilities. The booster connection and filtration systems are integrated into the storage tank with ease. They can be used safely for many years without decomposing or rusting.

Water Tank Prices

Manufactured in-line with international standards and eco-friendly concept, Karmod water tank models has a long-life system of preserving water and chemicals in a safe manner. They are produced in accordance with open and underground area conditions. The quality of stainless tanks have been proven with the superiority of long-lasting usage which does not allow corrosion to form.

Water tank prices might be the most searched subject among the clients. That is because, water tank models are quite resistant to impacts. However, this is not known widely among the people who want to buy these tanks. Meaning, these water tank models can be used for a long time after purchase. Thus, you do not need to search for water tank prices for a long time.

Resistance to impact and UV sunlight advantages are among the features of polyethylene water tanks, which are produced with the new generation rotation technology. On the other hand, all the storage tanks are UV stabilized. Meaning, as mentioned above, they do not allow sunlight inside the tank. Water tank prices may be affected in accordance with high-quality materials used.

Polyethylene storage tanks, which are produced in heat-treatment furnaces and prepared with specially made molds that are unique to the products with rotation system, have a tolerance of ±%3 as a measure. Polyethylene tanks, which are modular, are produced as a whole in one piece. With their style of production, they do not need additional welding and connectors such as rivets. Polyethylene tanks, which are produced in accordance with the food regulations, are used safely for the storage of drinking water and liquid materials used in the food industry. They safely protect the nutrients stored inside and contributes to healthy living. Polyethylene products have a long-lasting usage feature and they are used for many years without requiring maintenance. They have sturdy, easy-to-clean, and odorless feature. It is especially recommended to prefer blue-colored products when used outdoors to prevent formation of algae.

Polyethylene Water Tank Properties

First and foremost, there are two important points in liquid storing which are impermeability and vaporization. Water storage tanks must preserve the liquid inside safely against these two risks. The polyethylene water tank features have prominent advantages that innovate the liquid storage tanks with its quality and functionality. Polyethylene is fit to store raw nutriments (food grade). Linear low density polyethylene (LLDPE) have a feature of being 100% recycleable raw material. It prevents vaporization and algae formation with its high-resistant thickness and UV stabilized features. Water tanks made from polyethylene do not corrode when get into contact with dirty water or dirt surface from outer surface. Because of their superiority that allows them to not get deformed from outer factors makes them the most preferable among storage tanks.

Polyethylene water tanks produced with new generation rotation technology also have the advantage of resistance against sunlight and impact. Polyethylene storage tanks, which are produced in heat-treatment furnaces and prepared with specially made molds that are unique to the products with rotation system, have a tolerance of ±%3 as a measure. Modular polyethylene tanks are produced as a whole in one piece. With their style of production, they do not need additional welding and connectors such as rivets. Polyethylene tanks, which are produced in accordance with the food regulations, are used safely for the storage of drinking water and liquid materials used in the food industry. They safely protect the nutrients stored inside and contributes to healthy living. Polyethylene products have a long-lasting usage feature and they are used for many years without requiring maintenance. They have sturdy, easy-to-clean, and odorless feature. It is especially recommended to prefer blue-colored products when used outdoors to prevent formation of algae.

Thanks to their lightness, polyethylene water tanks can be transferred quite easily. The place of use can be changed on demand without causing any harm. Thanks to its 100% fully recyclable feature, polyethylene tanks go under the environmentally friendly category. They can be repaired very easily if possible usage errors occur. They show endurance from 5°C to 50°C. LLDPE polyethylene tanks show resistance against many chemicals, we recommend making contact with our authorized personnel for general chemical resistance table. Polyethylene water tanks are manufactured in three different types. These are, horizontal rectangle, vertical cylindrical, and horizontal cylindrical polyethylene tanks. Vertical storage tanks are standard manufactured in 18 different sizes ranging from 5 liters to 25.000 liters. Large tonnage water tanks are especially preferred in industrial facilities to store water and chemicals. Different chemicals like Water, diesel, acid, liquid paint along with nutriment liquids can be stored. Large tonnage storage tanksa re also preferred in rain harvest, which has become widespread in our country very recently. Likewise, it has functional use in fire water storage by being buried underground in factories and large industrial facilities. As for horizontal cylindrical tanks, they are manufactured in 9 different sizes ranging from 200 to 5.000 liters. Also, horizontal cylndrical prismatic polyethylene water tanks are manufactured between 100 - 500 liters and generally preferred in garden and home use.

Water Tank Types

Factors such as the material used in production, manufacturing style, tank type, area of use determine the types of water tanks. In accordance with types of materials and metals used in production, polyethylene, polyester and stainless metal water tanks are present in general grouping. These tanks are produced in the shapes of vertical cylindrical, horizontal cylindrical, ellipse, and prismatic in accordance with material and mold features. Karmod, which has been producing liquid storage tanks in the industry since 1986, produces more than a hundred models in all of the water tank types.

Polyethylene water tanks are produced between 50 liters and 25 tons with the use of LLDPE polyethylene material. They are manufactured in 3 different types, vertical cylindrical, horizontal cylindrical and prismatic rectangle, with specially made molds that are unique to the products.

Polyethylene storage tanks have a rich 31 different models and sizes. They protect human health with the food safety standard that they have. Polyethylene tanks are manufactured with standard white and blue color. Both of these colors protect against UV light and blue polyethylene tanks are especially recommended for the outdoors usage. Blue tanks provide full protection against algae formation when used outdoors. Polyethylene tanks can be manufactured with green, yellow, orange and black alternatives on the demand of customers and corporate identity applications. Polyethylene water tanks, produced using special molds with state-of-the-rotation art technology, have the advantage of resitance against impact and long-lasting usage. The materials used in polyethylene tanks are in the framework of European standards and they are safe for human health. No dyes or chemicals are used during the manufacturing process. With the system developed, together with open space uses, the production of special polyethylene tanks for underground uses is also carried out.

Polyester water tank types are produced in the shapes of vertical and horizontal cylindrical, horizontal ellipse, and prismatic. They can be manufactured between 200 and 100.000 liters. Polyester tank types that are between 20 and 100 tons are especially preferred for underground uses. Underground tanks are specially produced for underground usage thus gaining high resistance. High-tonnage tanks are used as rainwater harvesting and factory fire extinguishing storage tanks with special production in accordance with the production facility regulation.

Stainless water tanks are produced as vertical, horizontal cylindrical and prismatic. In the production, AISI 304 – 316 quality stainless sheets that are fit for nutriments are used. With its special metal structure, it is resistant to corrosion and does not allow rusting. With the specially produced technique, the tank is sealed and quality tests are also carried out. Stainless tanks, which are produced in the range of 500 to 100,000 liters, also have special supports that are made of stainless material. In large tonnage tanks, a ladder is placed on top of the tank and has ergonomics of use. In all models, the inner and outer surfaces of the tank have a smooth slippery surface and do not easily get dirty. Cleaning the tank is very easy. Necessary standard applications have been made for the water booster connection, discharge outlets and level indicator outlets on the tanks. The use of connected storage tanks is suitable for higher tonnage storage tanks. On-site production and assembly can be done in narrow entrance areas. It can be produced with a mixer.

Innovative Plastic Water Tank Production

What Could Be More Important Than Water In Human Life?

Karmod Plastik has been the leading water tank manufacturer in Turkey in the production of liquid storage tanks since 1986. With our production facility located in Istanbul, we export to every region of Turkey and to more than 35 countries around the world. Responding to a wide range of needs, from individual use to industry - factory use, we produce innovative and cost-effective plastic and polyester water tanks. We are aware of how vital your satisfaction is to our continued success and we manufacture all types of water tanks to be high quality with our factory warranty. By using modern production technology, we are leading the development of liquid storage tank solutions in Turkey and in neighboring countries. You can contact us immediately to get information and purchase from the experienced staff of Karmod Plastik. With our Plastic Water Storage Tanks products, we ensure the healthy storage of water, which is the greatest need of human beings in all areas of life. We produce our tanks with the awareness of responsibility, which are produced using the best raw materials specially purchased from Europe and materials in compliance with the food regulations. Karmod Plastik, the first company that comes to mind when it comes to fiberglass water tank production, always works to reach the best quality. We manufacture liquid storage tanks in line with international standards and quality with the granular polyethylene raw material and fiberglass FRP materials we use. In this way, our water tanks are very different from their counterparts in the market and have superior features.

We have different water tank solutions ranging from storage solutions in basement floors to house indoor solutions. We produce tanks with alternative features with our plastic, polyester and stainless water tank products. Our company, which also produces silo tanks or conical storage tanks for industrial industrial storage solutions, produces the most suitable solutions for you by producing mold designs specifically for your needs. We are waiting for you to provide you with solutions to all your liquid storage needs. Give us a call now, tell our experienced staff about your storage needs and get to know the difference of Karmod Plastik solutions.

EN

EN

DE

DE

FR

FR

IT

IT

ES

ES

PT

PT

RU

RU

AR

AR

BG

BG

SR

SR

GR

GR

SQ

SQ

RO

RO

PL

PL

HU

HU

CZ

CZ

HR

HR

AZ

AZ

GE

GE

AM

AM

IL

IL